InsigH2t aims to understand how pressure affects the turbulent burning rate, thermoacoustic response, and emission performance of premixed hydrogen flames at relevant gas turbine operating conditions. Hydrogen can potentially unlock zero carbon large-scale power generation but poses significant challenges in terms of stability and emissions as a fuel in gas-turbines. However, we currently lack the fundamental understanding of how pressure affects turbulent flames which is crucial for efficient and stable gas-turbines operation.

In alignment with the Strategic Research and Innovation Agenda of the Clean Hydrogen Joint Undertaking, the project also addresses industrial challenges through the involvement of two gas turbine Original Equipment Manufacturers (OEMs) to facilitate a rapid transfer of improved combustion methodologies and understanding towards application in operational power plants. InsigH2t’s contributions align with the objectives of the EU Green Deal, Hydrogen Strategy, offering a tangible pathway towards a more sustainable energy future. Additionally, it supports the manufacturing of key technologies in Europe, in line with the Net-Zero Industry Act (NZIA) goals of strengthening manufacturing of clean-tech in Europe.

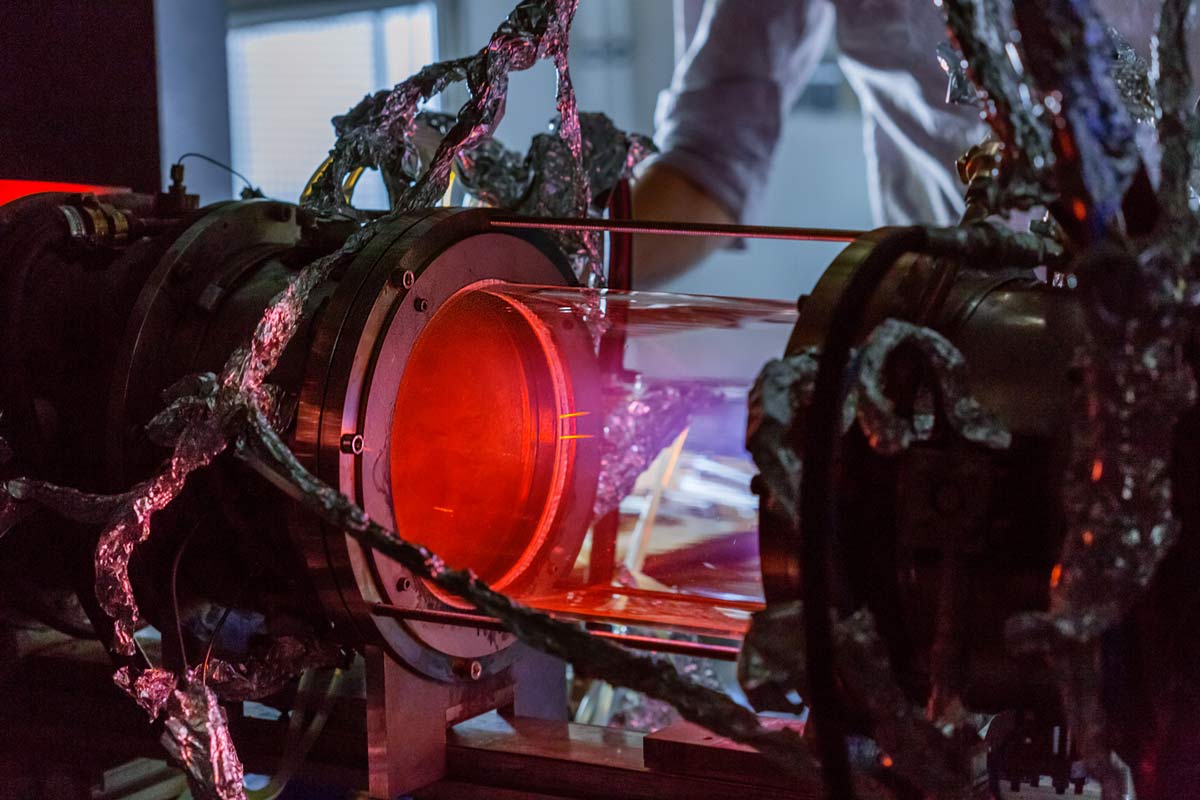

One of the biggest challenges facing the development of zero carbon, hydrogen fired gas turbines for power generation is the lack of fundamental understanding of how hydrogen flames behave under elevated pressure. The aim of the InsigH2t project is to solve this problem. The InsigH2t consortium brings together world leading researchers and industry partners with unique capabilities who will perform groundbreaking experiments and numerical simulations from which new predictive tools and design methodologies will be developed for safe and efficient operation of hydrogen fired gas turbines.

InsigH2t leverages unique high-pressure experimental facilities with access to advanced optical measurement methods, coupled with cutting-edge direct numerical simulations to focus on a selection of simple canonical flames that are paradigms of more complex industrial burner geometries and configurations. This will form the foundation for the development of advanced models and enhanced design tools, empowering industrial OEMs to reduce the development time and costs of hydrogen combustion technologies. Through new science-based predictive capabilities, InsigH2t aims to accelerate the deployment of clean, reliable, and efficient hydrogen-fired turbines.